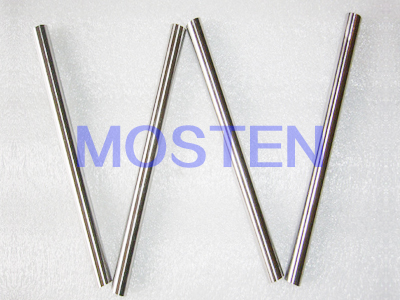

Tungsten Rod & Bar

Tungsten rod/bar can be divided into two categories: one is used for finished products, the other is semi-finished rough bar for stretching wires, the processing methods of which include rotary forging and groove rolling. We own exquisite processing technology. Our tungsten rod/bar has the advantages of high electrode strength, high oxidation temperature resistance, long service life and strong corrosion resistance.

Our company can produce tungsten rods/bars of any length according to customer's drawings. The surfaces of tungsten alloy rods/bars are chemically cleaned to remove all lubricants and oxides. Tungsten rods/bars are mainly used as heaters, support columns, feeders and fasteners in high temperature furnaces in vacuum or reduction environment. They are also applied in the light source of illumination industry, the electrode and rare earth melting in the glass industry, and welding equipment.

Tungsten rods/bars can be made into tungsten wires. Due to the high hardness, low mechanical wear, and resistance to fusion, tungsten materials are widely used for electrical contacts in the electrical systems of automobile distributors, automobile engine voltage regulators and so on. Besides, tungsten rods/bars can be used for electrodes, electric tube bars, side bars, supply wires, brackets, gas lamp electrodes, high-power incandescent filaments, filaments of electronic tubes and cathodes of emission tubes, crankshafts of advanced vehicles, etc.

Swaged Tungsten Rod

Swaged tungsten rods are made by continuous forging. After processed on the centerless grinding machine, the integrity and accuracy of Swaged tungsten rods’ surface diameter are improved. The rods can be processed into various shapes, while the most common shape is a cylindrical bar. After forged, the tensile strength of tungsten rods will be greatly improved from 1050 MPa to 1200 MPa. The productions of swaged tungsten rods are made by forging and sintering of tungsten billets.Tungsten Support Rod

Tungsten support rods, as structural elements in vacuum furnace, have better performance on thermal resistance, mechanical stability, configuration and service life. In the meantime, tungsten support rods can also be made into various styles. They can be processed into strips, sheets, or poles according to different hot zone configurations. Comparatively speaking, tungsten support rods are the best choice for excellent high temperature applications. They have provided superior mechanical and strength properties for the users.Sintered Tungsten Rod Bar

Sinter tungsten rods/bars are often used in high temperature vacuum furnaces such as sapphire single crystal furnaces. The density of sintered tungsten rods/bars is 18.3 g/cm3, which is close to the theoretical density of tungsten. They have the property of high temperature resistance. The melting point of sintered tungsten rods/bars can reach 3380 ℃. The rods/bars also have the characteristic of high creep resistance.

| Diameter of Our Regular Tungsten Wire, Rod, Bar | |||

| Material | Shape | Diameter inch | Diameter mm |

| W | Tungsten Wire | 0.005" | 0.127 mm |

| W | Tungsten Wire | 0.006" | 0.1524 mm |

| W | Tungsten Wire | 0.007" | 0.1778 mm |

| W | Tungsten Wire | 0.008" | 0.2032 mm |

| W | Tungsten Wire | 0.009" | 0.2286 mm |

| W | Tungsten Wire | 0.01" | 0.254 mm |

| W | Tungsten Wire | 0.0125" | 0.3175 mm |

| W | Tungsten Wire | 0.015" | 0.381 mm |

| W | Tungsten Rod/Bar | 0.02" | 0.508 mm |

| W | Tungsten Rod/Bar | 0.03" | 0.762 mm |

| W | Tungsten Rod/Bar | 0.05" | 1.27 mm |

| W | Tungsten Rod/Bar | 0.1" | 2.54 mm |

| W | Tungsten Rod/Bar | 0.2" | 5.08 mm |

| W | Tungsten Rod/Bar | 0.3" | 7.62 mm |

| W | Tungsten Rod/Bar | 0.5" | 12.7 mm |

| W | Tungsten Rod/Bar | 1" | 25.4 mm |

| W | Tungsten Rod/Bar | 1.5" | 38.1 mm |

| W | Tungsten Rod/Bar | 2" | 50.8 mm |

| We can produce the tungsten wires, rods and bars according to your requirement. | |||

| Chemical Composition of Pure Tungsten Wire, Rod, Bar | |

| Element | % maximum |

| C | 0.01 max |

| O | 0.01 max |

| N | 0.01 max |

| Fe | 0.01 max |

| Ni | 0.01 max |

| Si | 0.01 max |

If you would like to purchase tungsten rod & bar from China, please don't hesitate to Contact Us.